Your partner in Power Electronics

Engineering. Consulting. Experience in Power Electronics at your service.

Power Smart Control team can help you from the very beginning, starting with the concept & initial studies up to the complete development of your power electronic system according to your needs.

PSC actively participate in research projects, so we always know and master the latest technologies.

Technical skills training. Improve your team performance.

Encouraging learning you are creating more engaged and productive workers.

High quality. Choose content developed by experienced, professional instructors to ensure that your team is getting the most up-to-date, easily understood lessons.

Our areas of expertise:

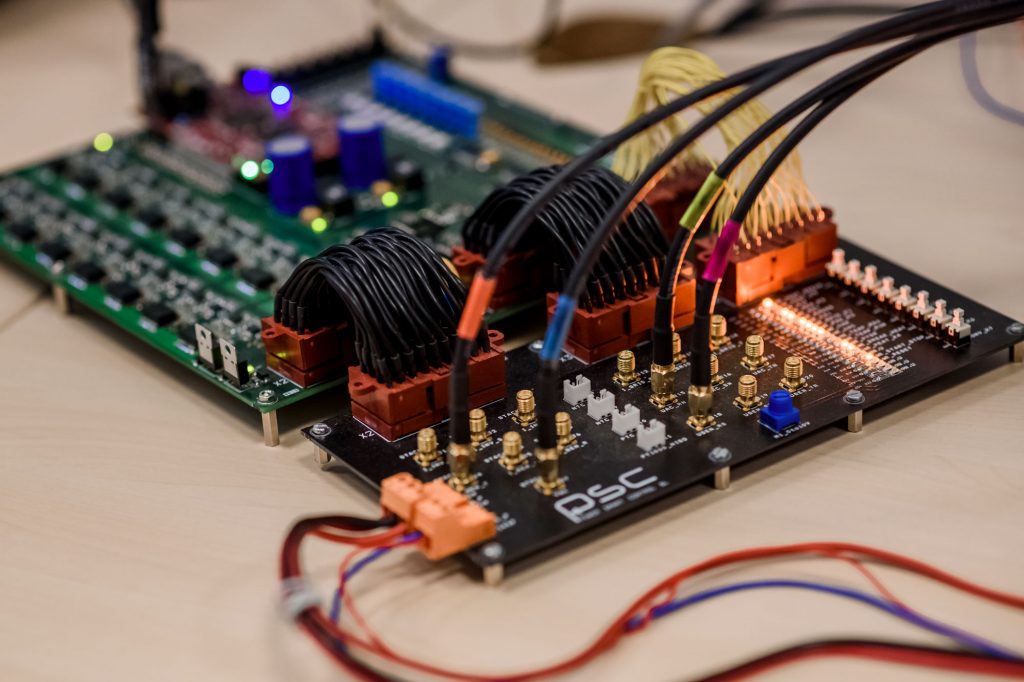

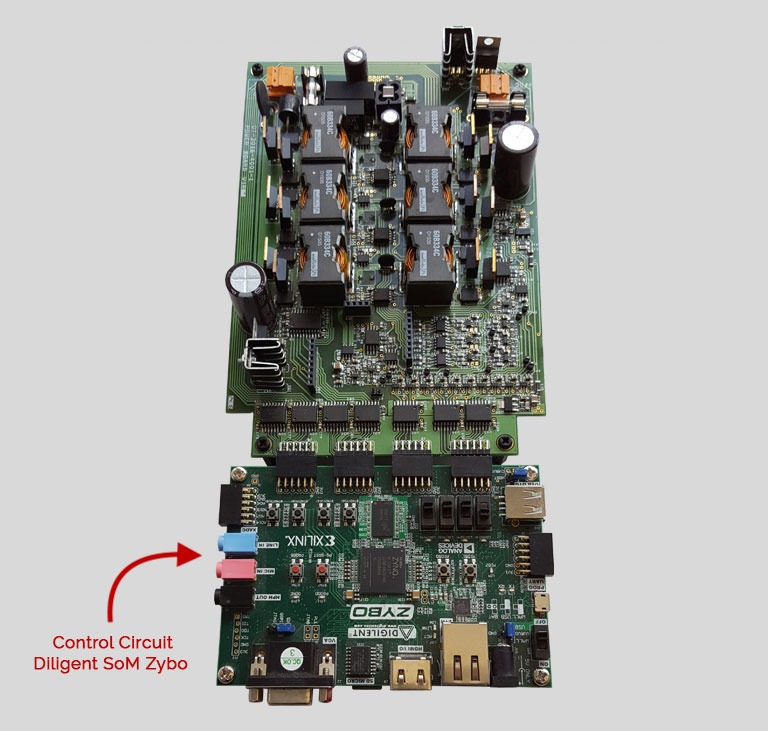

We can develop the control board for your power electronics system, the custom Hardware-in-the-Loop to help you in the development process of the control algorithm, the IP core and even the Test Bench to validate your final control board produced before the integration in the final system.

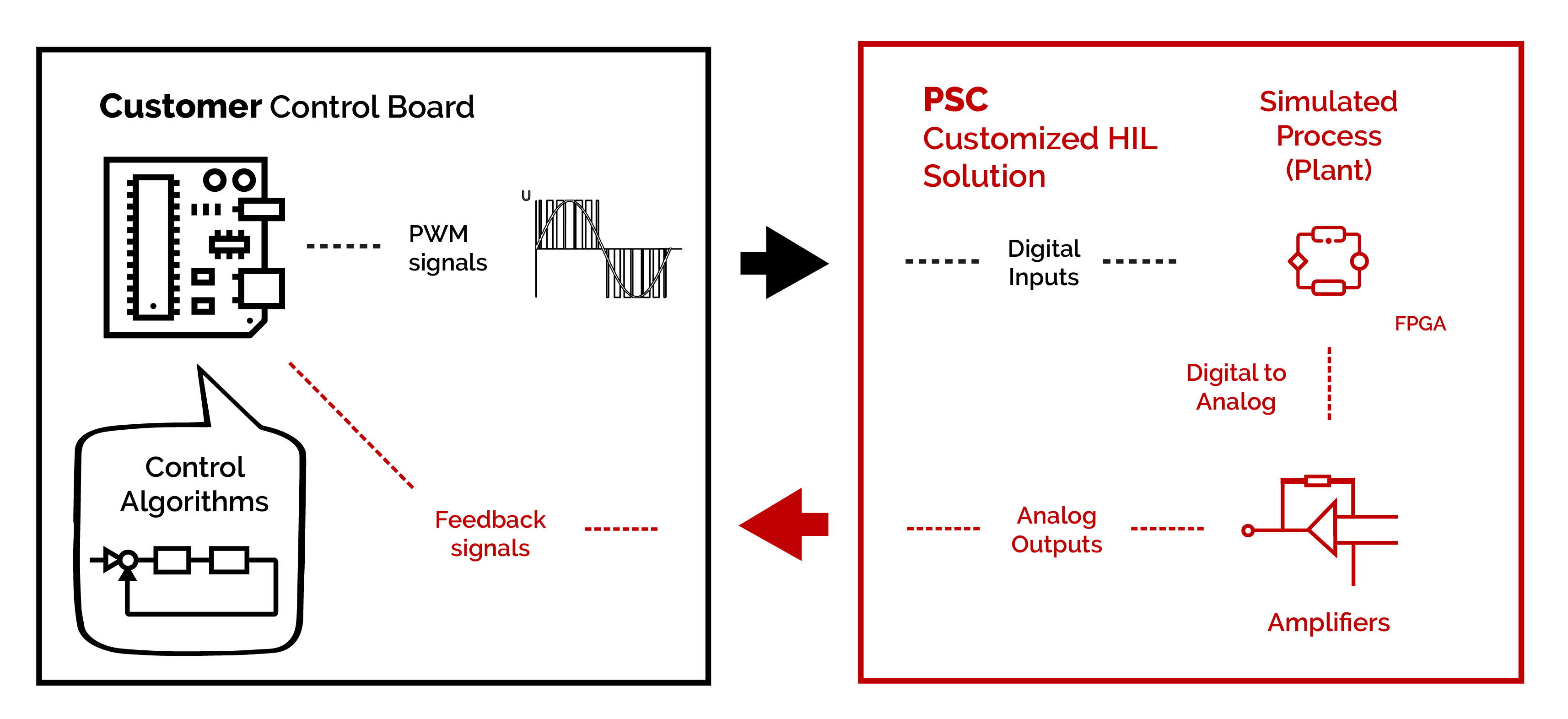

Customized HIL

In a highly competitive and demanding environment, it is important to reduce both development costs and time to market while delivering high quality and reliable products.

Hardware-in-the-loop (HIL) is a cost-effective technique that allows the power converter to be replaced by a real-time simulation model, avoiding building prototypes in the early stages for the development and validation of the controller.

Using commercial HIL solutions is an option, but it could be a time-consuming task and divert your resources from your core business.

Power Smart Control bets all its experience and know-how going one step further: we develop your customized HIL system, from the modeling of the system to the final test of the customized hardware.

We provide your team of design engineers with a HIL Solution to which they can connect remotely, perform all kinds of tests on the system thanks to its virtual Grid Emulator and visualize all the internal variables of your control system thanks to an advanced oscilloscope function. All this is in addition to a hardware adapted to your system to the smallest connection.

Fully adapted HW interface to customer control units

🔺 Customized voltage I/O (voltage level and bandwidth)

🔺 Customized current I/O (current level and bandwidth)

🔺 Customized temperature I/O

🔺 Specific driving signals of contactors

🔺 Bus Can drivers, 485 drivers, etc.

🔺 Ethernet, USB 2.0

Fully adapted models for customer applications

🔺 Customized grid model (Voltage dips, unbalanced operation, harmonics, line impedance)

🔺 Customized generator – motor model (Induction motor-generator, PMSM, DFIG, Switched reluctance motor, etc.)

🔺 Customized models for energy storage elements (batteries, batteries & BMS, ultra-capacitors, etc.)

🔺 Customized models for energy sources (PV panels, wind models, fuel-cells, SMES, flywheels, etc.)

Special functions

🔺 Grid codes compliance (Voltage dips, unbalanced operation, harmonics, line impedance, inter-harmonics, overvoltage, Frequency variations, Islanding filters)

🔺 Islanding detection

🔺 Failure modes injection

🔺 Power supply consumption emulation

🔺 Power losses emulation (inductors, IGBT, SiC, etc.)

Fully adapted SW user interface & oscilloscope function

🔺 Customized plots and graphs (PV curves, grid operation plots, phasor plots, etc.)

🔺 Customized schematics

🔺 Configurable parameters

🔺 Contactor returns control

🔺 Failure test definition

🔺 Fully customization of variable names (according to project specifications Induction motor-generator, PMSM, DFIG, Switched reluctance motor, etc.)

|

|

IP Cores

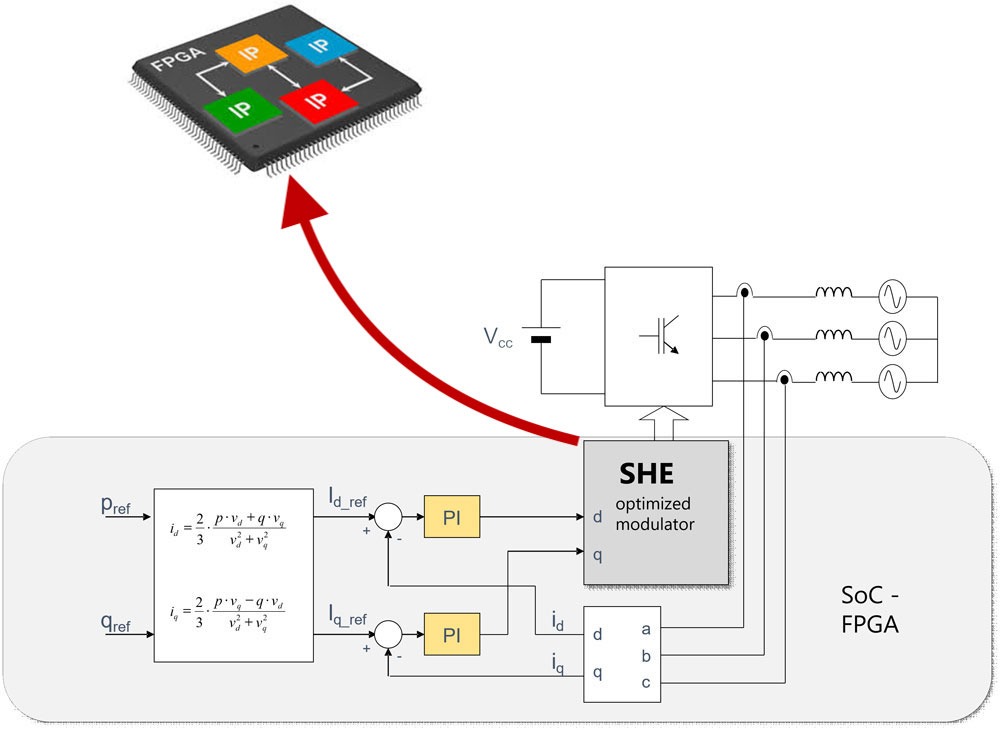

Power Smart Control provides IP Cores for the Digital Control of Power Electronics. Control structures and function blocks for SoC and FPGA based controllers:

🔺 Pi, PID, P-Resonant

🔺 DQ structures, alfa-beta structures

🔺 PLL and sequence separators

🔺 Feedforward compensations

🔺 Sampling techniques

🔺 Advanced modulators:

🔺 Optimized SHE (scalar or vector control)

🔺 Space vector modulation

🔺 Overmodulation techniques, etc.

🔺 Others

Advanced control algorithms. Example of IP Core: Optimized SHE modulator for vector control

Test Benches

Considering the complexity of the control boards of current power electronics systems used in Energy, E-mobility or Aerospace applications it is necessary to validate properly these control systems before they are installed onsite or simply tested with the real systems.

Our automatic Test Bench tailor-made designs perform a completely automatic verification of customer control units helping the manufacturer to deliver a 100% functional control unit: zero errors, maximum quality.

Control Board

Digital Control improves performance, but it can be a real challenge if you don’t master the technology:

🔺 New control algorithms & optimized modulators

🔺 New digital platforms

🔺 New design tools and methodology

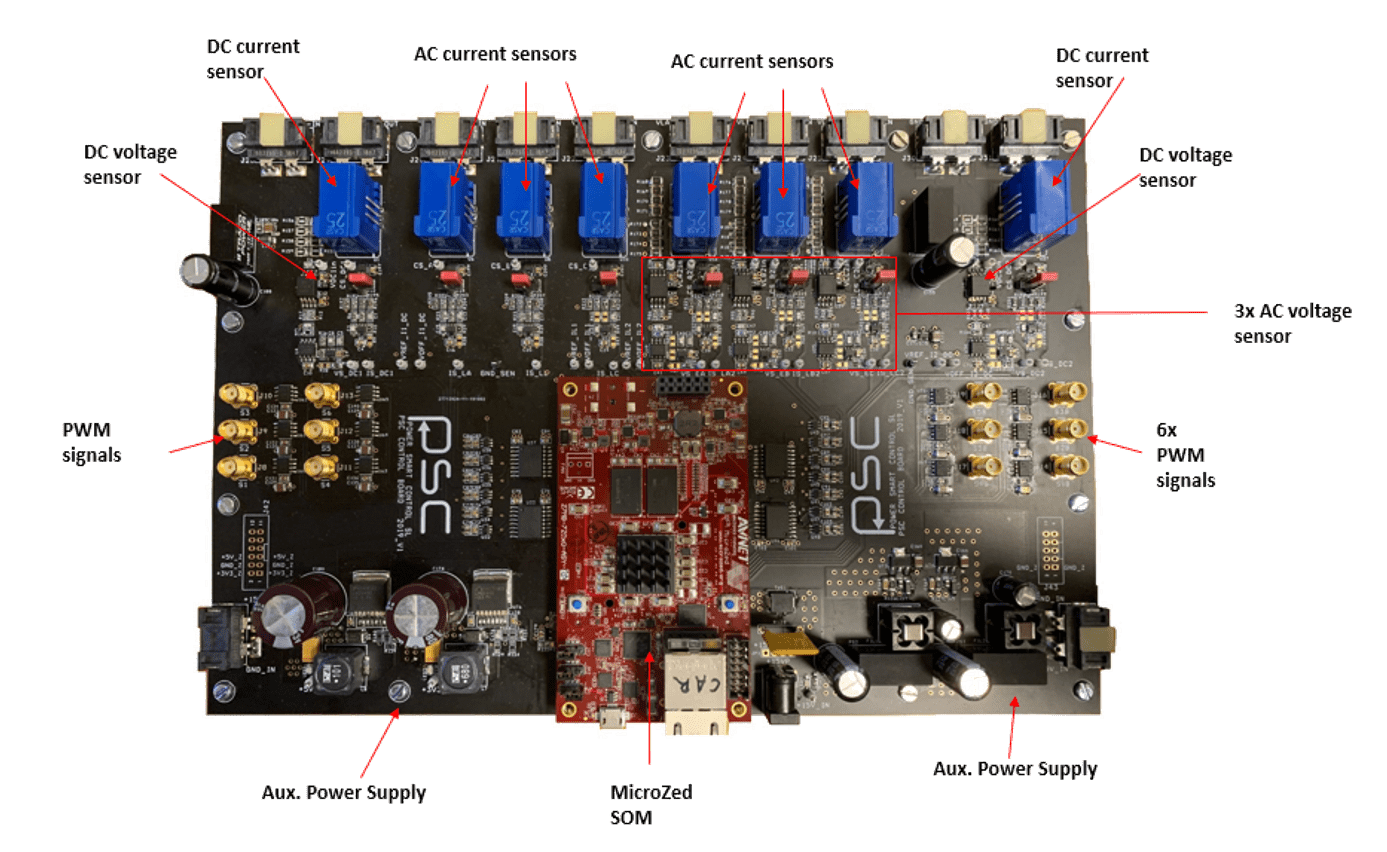

We have designed a Universal Control Board including up to 12PWM signals, with integrated current and voltage sensors, Power Supply, and communication protocols (Ethernet, CAN, USB 2,0).

Do you need any modification? It is completely customizable, and we will do it for you.

Applications:

🔺 Wind Turbine Back-to-Back Converter

🔺 Photovoltaic Inverters (2 inverters in parallel)

🔺 Railway Inverters (2 inverters in parallel)

🔺 High power DC-DC multi-phase (3Ph interleaving Buck-Boost Converter)

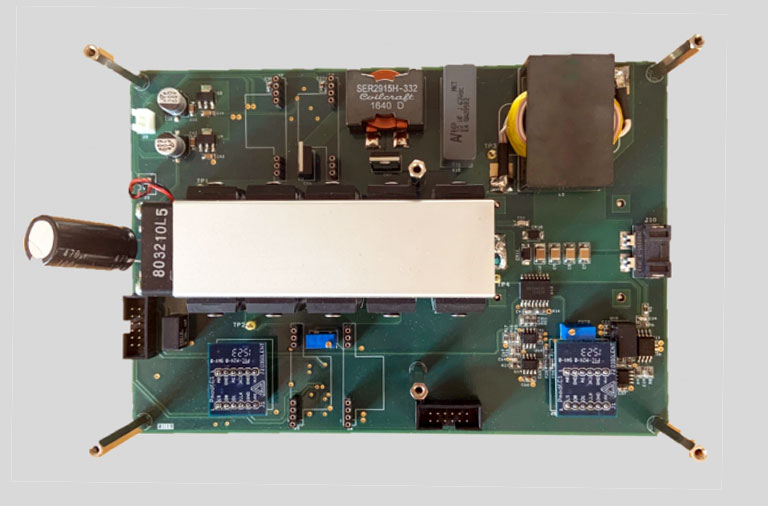

Desktop Power Electronics

At present, converter control enables functionality and communications. In the near future, these capabilities should grow exponentially, endowing the converter with remarkable intelligence and adaptability to operating conditions.

Digital control platforms will play a key role in this process.

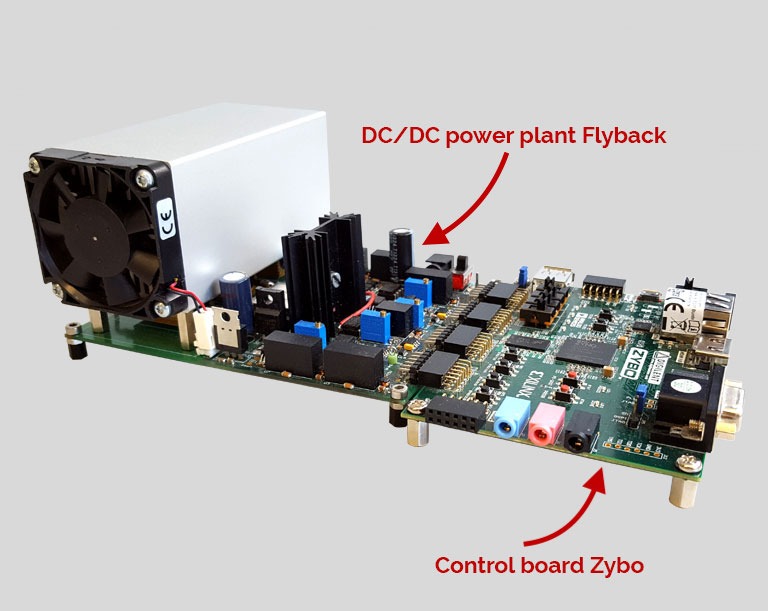

Power Smart Control proposal to enter into digital design and become an expert in new System-on-Chip devices is based on the use of Desktop Power Electronics development boards, scaled-down prototypes of versatile power converters connected to cost-efficient SoC development board.

This is a perfect tool for beginners to initiate in the digital control of power converters using SoC devices.

For the medium-advanced level firmware engineers, this option provides the opportunity of testing the control algorithm directly on its desktop. This reduces drastically the developing time and cost of the debugging process on the real converter.

Get more information.

Flyback DC-DC Converter

3-Ph front to front Inverter – PFC Rectifier

Full-Bridge Phase Shifted DC-DC converter

Customized Design & Consulting

We can help you with your power electronics projects

Do you need to develop your product faster? Power Smart Control have wide experience in advanced Power Electronics and Energy Management applications using innovative technologies, the latest components and smart solutions.

Our engineering services:

Our areas of expertise and customers are related to sectors as:

As an added value, Power Smart Control can also design and provide your own custom Hardware in the Loop (HIL) system for real-time simulation in the control development process. Visit our product section.

We are experts in Digital Control

| CONTROL | POWER CONVERTERS | FIRMWARE | TEST |

|---|---|---|---|

| Dynamic Modelling | EMI Filters Design | FPGA and SoC Based Universal Control Board | Customized Hardware in the Loop (HIL) |

| Control Design | Magnetic Components Optimization | Control IP Cores | Test Bench Design |

| Reference Designs for Simulation | Lay-Out, Busbar and Snubber Design | Ethernet, CAN and other Communication Protocols | Scale-down Prototypes Design and Production |

| Cooling System Optimization | Real-Time Variable Login for FPGA Variables Monitorization |

Training Courses

Education is in our DNA. We know the value of knowledge and time.

Expand your engineering excellence with the right training: your development team may need a capability boost by upskilling.

Our key success factors:

🔺 Individual training courses adapted to your needs.

🔺 Experienced trainers.

🔺 From the basics to the cutting-edge technology: we can provide training on basic power electronics concepts as well as specific, specialist expertise for your applications.

Our courses will provide an up-to-date revision of the power electronics main topics, design techniques and PSIM and SmartCtrl basic and advanced use.

In addition to PSIM & SmartCtrl basic use, every power electronic circuit will be simulated using PSIM. Therefore, deep knowledge about using PSIM will be acquired with any of the other training focused on specific applications.

The general concepts that can be covered include the following topics:

| Course Structure | Topics | Hours |

|---|---|---|

| Fundamentals | Topic 1: Power Electronics Basics and DC-DC Converters | 24 |

| Topic 2: Analog & Digital Control of DC-DC Converters | 24 | |

| Power Stage Design | Topic 3: Design and optimization of inductors for power electronics applications | 16 |

| Topic 4: Design of High-Frequency transformers | 8 | |

| Topic 5: Design and Optimization of Power Electronics Converters | 24 | |

| Topic 6: Thermal Management of Power Converters | 8 | |

| Topic 7: EMI Filter Design | 8 | |

| Power Electronics Applications | Topic 8: Design of Power Factor Correction (PFC) Rectifiers | 16 |

| Topic 9: Modulation Techniques for Single-Phase and Three-phase inverters | 8 | |

| Topic 10: Modelling and Control of Single-phase and Three-phase voltage Source Inverters | 24 | |

| Topic 11: Digital Control of Medium-High Power DC-DC converters | 24 | |

| Special Power Electronics Applications | Topic 12: Regenerative breaking modelling and control | 4 |

| Topic 13: Cascaded converters: modelling and stability analysis | 6 | |

| Topic 14: Modular converters based on DAB ISOP (input-series and output-parallel connection) | 4 | |

| Software | Topic 15: From basic concepts to advance simulations with PSIM & SmartCtrl | 8 |

| Electromagnetic Compatibility EMI-EMC | Topic 16: Understanding electromagnetic compatibility | 24 |