SmartCtrl

Control Design Software for Power Electronics

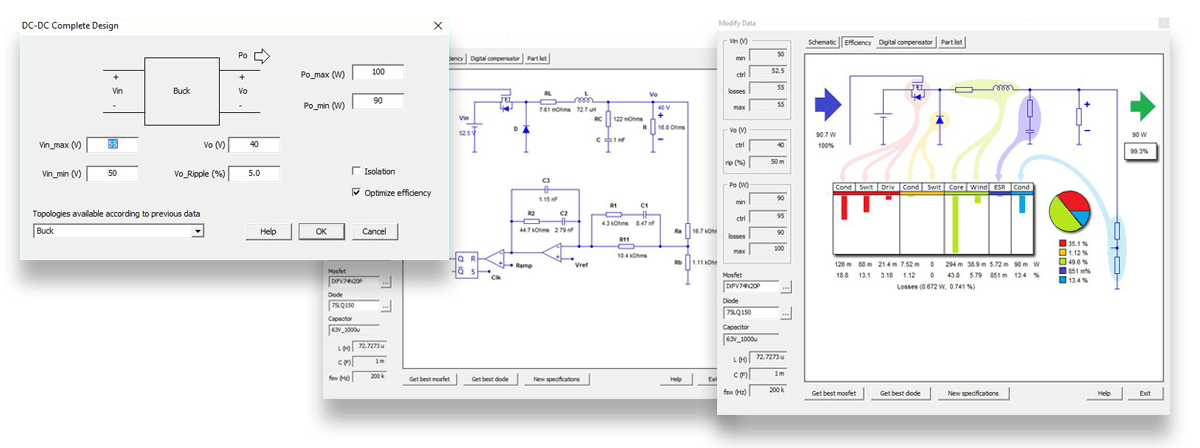

Complete Designs from Specs

![]()

Power stage and control design from specifications.

Data in Real-Time

Interactive plots allow you to choose the best control design, while waveforms, bodes, Nyquist and all output data are updated in real-time.

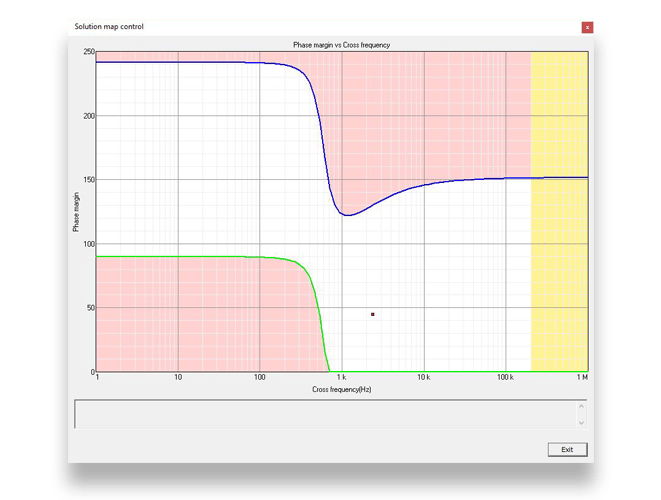

Solutions Map

![]()

The Solutions Map helps the user to choose the crossover frequency and phase margin. SmartCtrl presents a stable solutions space for every type of regulator.

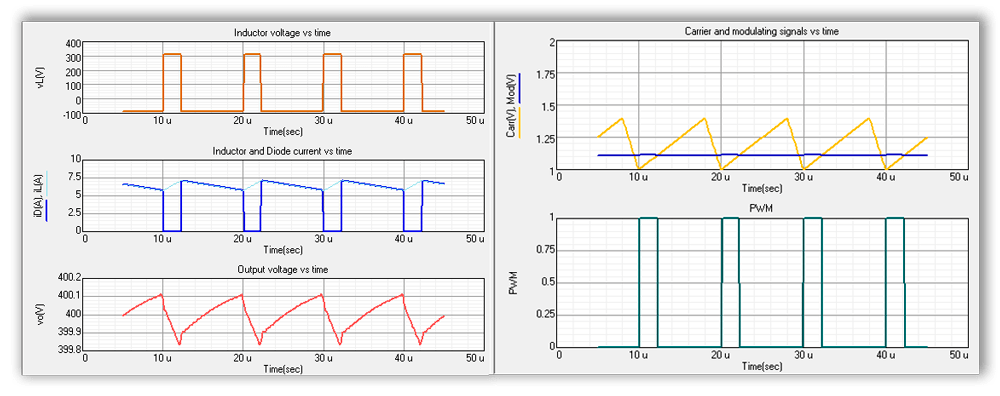

Steady-State Waveforms are Plotted

![]()

Inductor current and voltage ripple are plotted. The modulating signal output ripple is also shown.

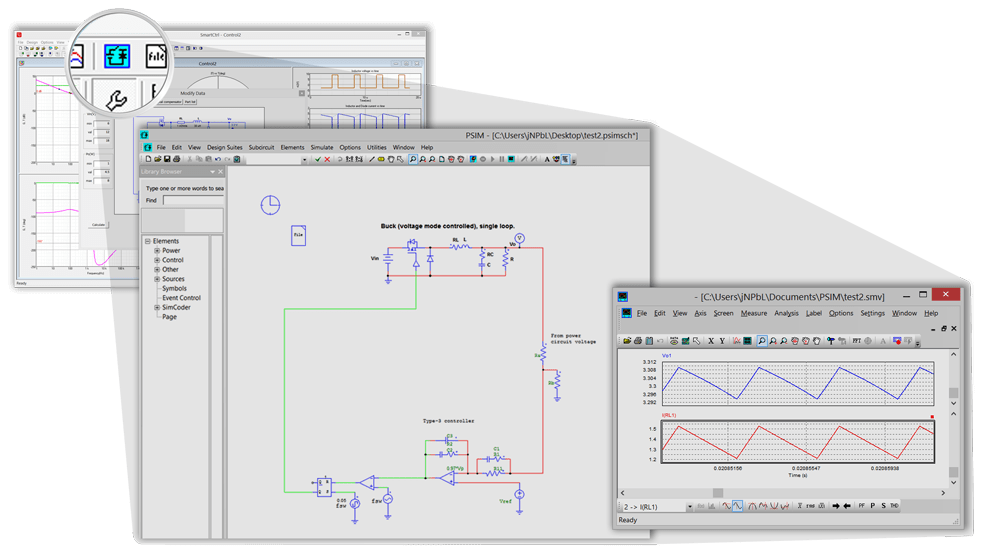

Electronic Circuit Simulator Integrated

![]()

Simulate the final design with a single click.

SmartCtrl is seamlessly integrated with the PSIM simulator. SmartCtrl automatically generates a ready-to-simulate PSIM schematic, containing the complete circuit, including the power stage and the control circuit.

With just one click on the PSIM‘s logo, one can export the entire circuit and simulate it.

Therefore, the simulation of the complete circuit designed in SmartCtrl can be performed in PSIM without the user having to draw any schematic: go straight from SmartCtrl design to Simview.

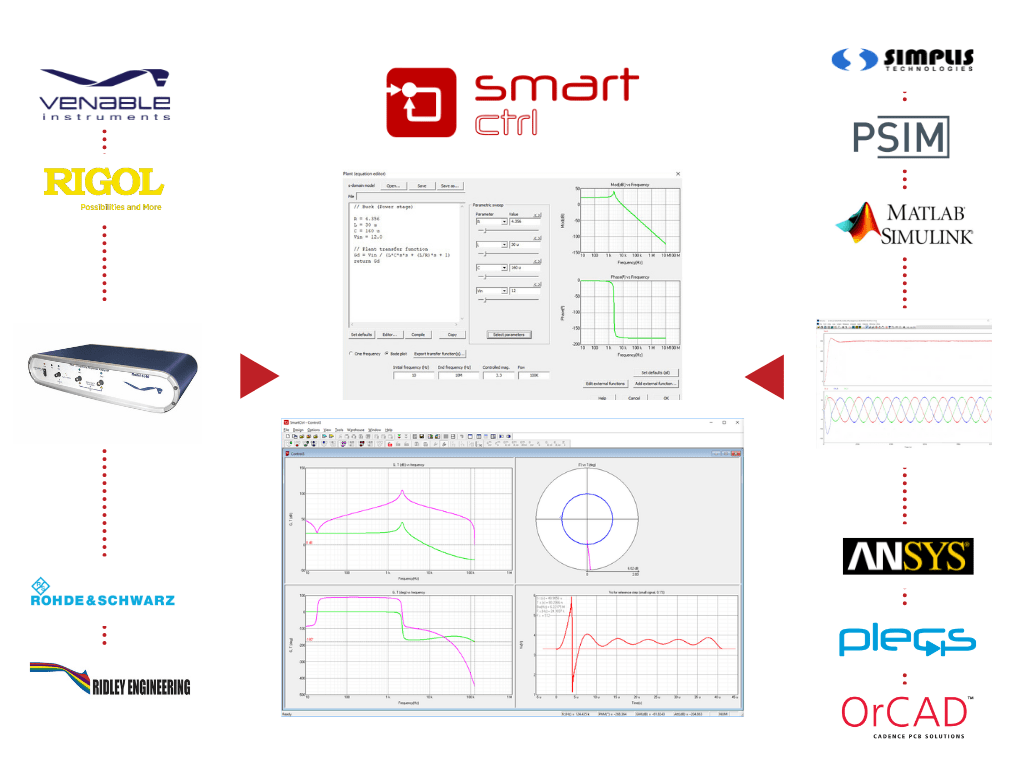

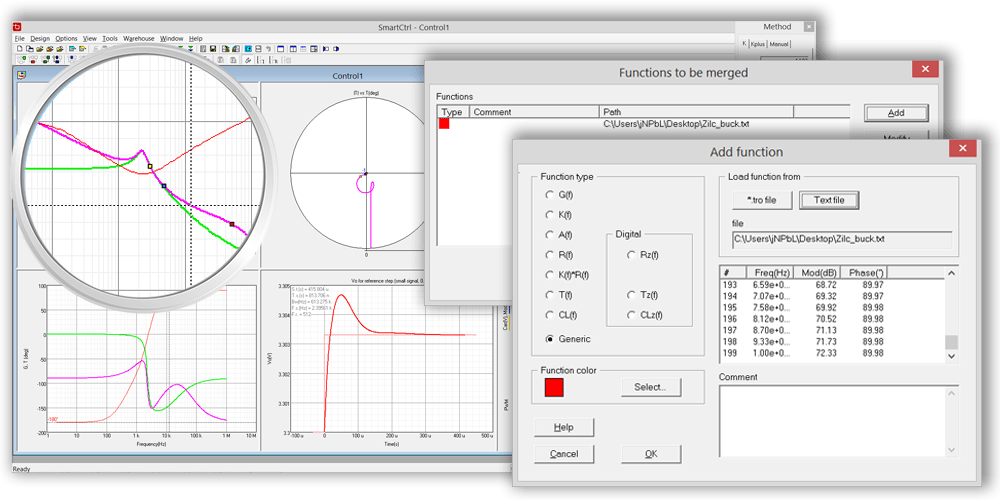

Import Frequency Response

![]()

Get the frequency response of your power converter from a simulator or frequency analyzer, import it to SmartCtrl and design your control.

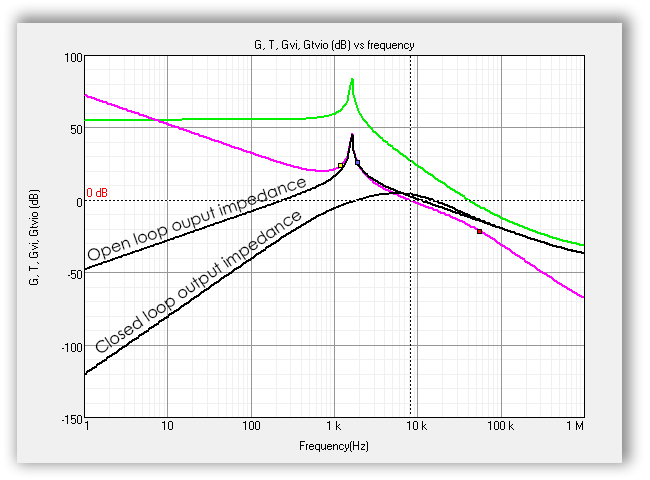

Audiosusceptibility and input-output impedances

![]()

For every DC-DC converter and control type, the transfer functions (TF), output voltage to input voltage (Audiosusceptibility) and output voltage to output current (output impedance) are shown as additional Bode Plots. These TF’s are very interesting for system converters. E.g. power distribution in satellites, etc.

There are many available transfer functions:

🔺 Open-loop audio susceptibility

🔺 Closed-loop audio susceptibility

🔺 Open-loop output impedance

🔺 Closed-loop output impedance

🔺 Open-loop input impedance

🔺 Closed-loop input impedance

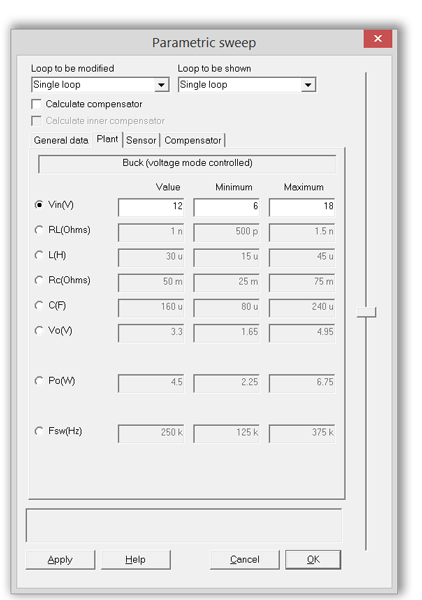

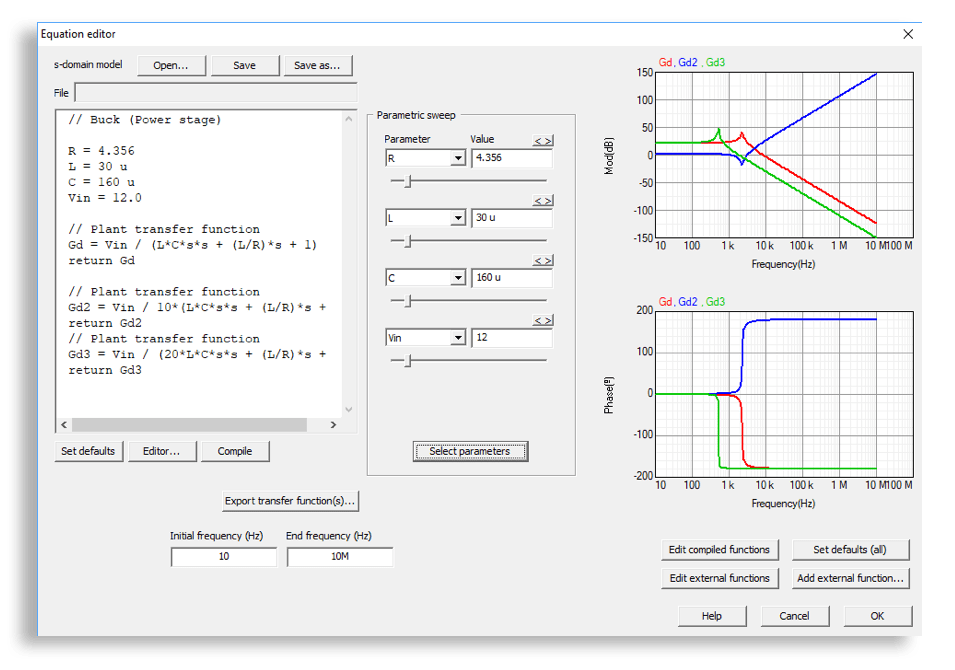

Sensibility Analysis

![]()

With Parametric Sweep you can perform a sensitivity analysis on every parameter of the plant, sensor and regulator and observe how this change affects the system. Data is updated in real-time.

🔺 Input and output voltages

🔺 Converter inductance, filter capacitor, cap ESR, etc.

🔺 Output power

🔺 Switching frequency

🔺 Sensor gain and bandwidth

🔺 Regulator resistors and capacitors

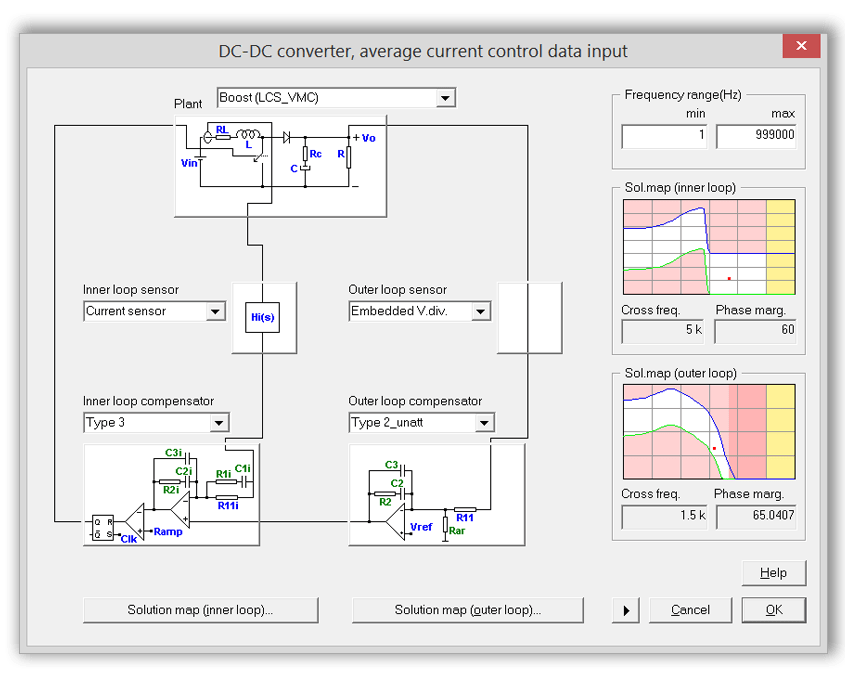

Multiloop Control Structures

![]()

Average – current control

🔺 Inner and outer compensator design

Peak – current-mode control

🔺 Compensating ramp design

🔺 High-frequency effects

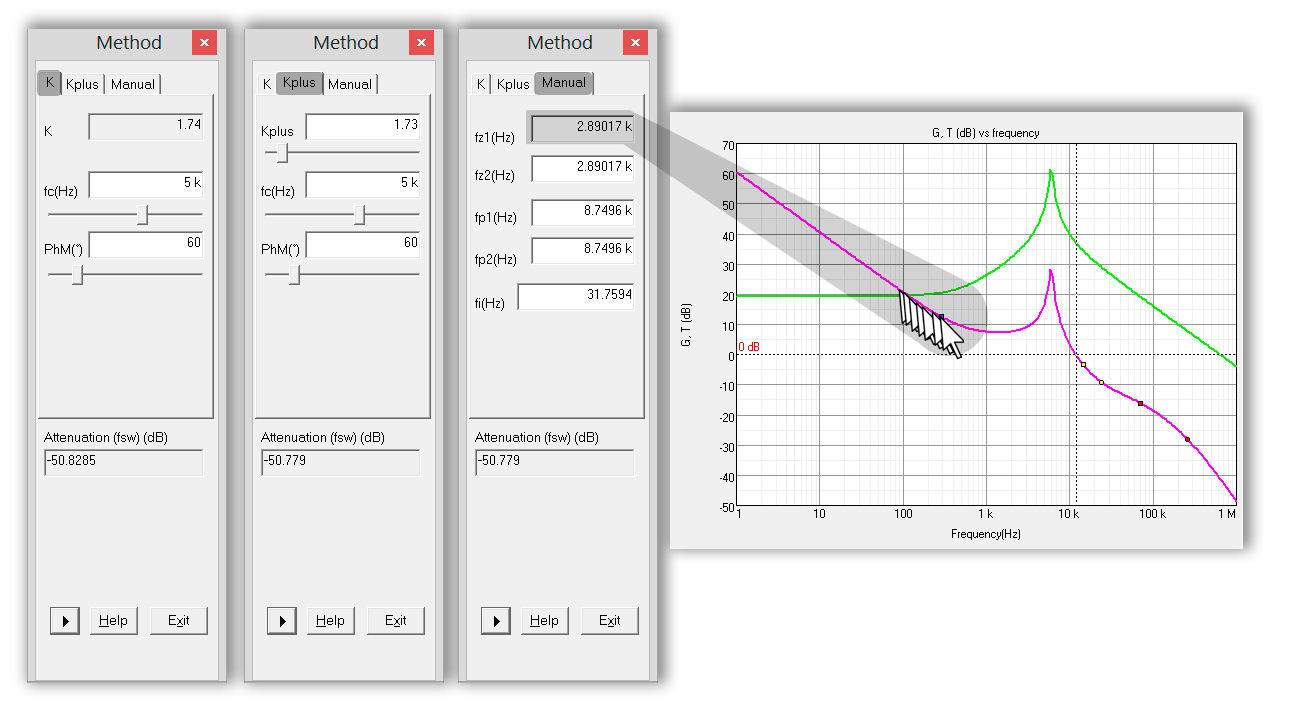

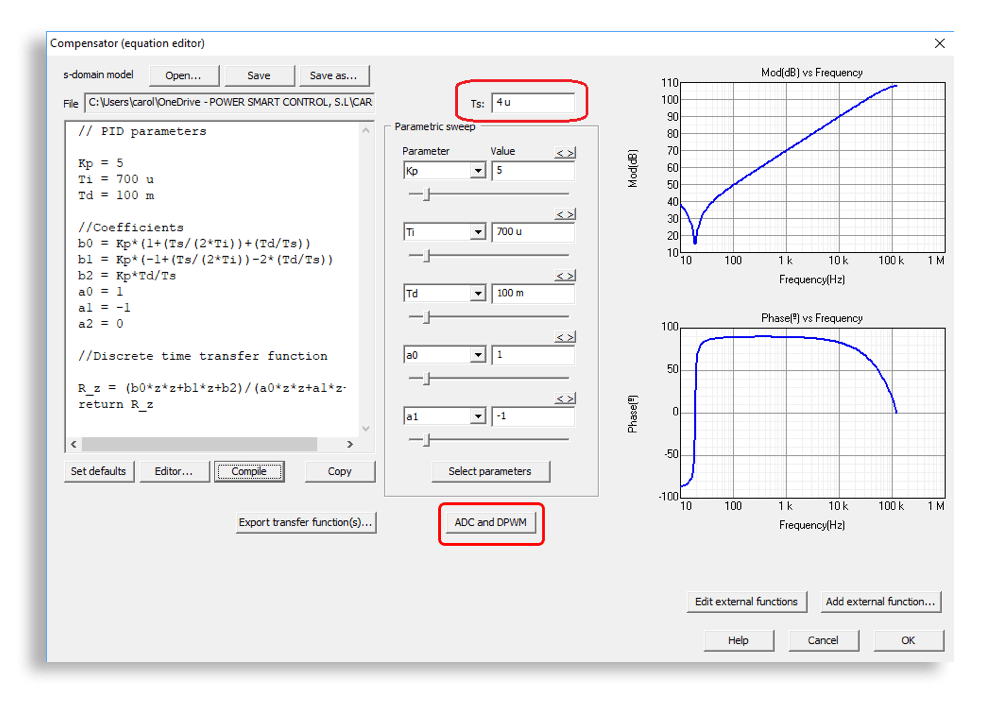

Compensator Design and Synthesis Algorithms

![]()

Design your control through the K method. From the desired MF and fc, the frequency of the zeros and poles is calculated.

Optimize the control either through the K plus method or manually. Then choose the poles and zeros frequency of the compensator with the simple click of a mouse.

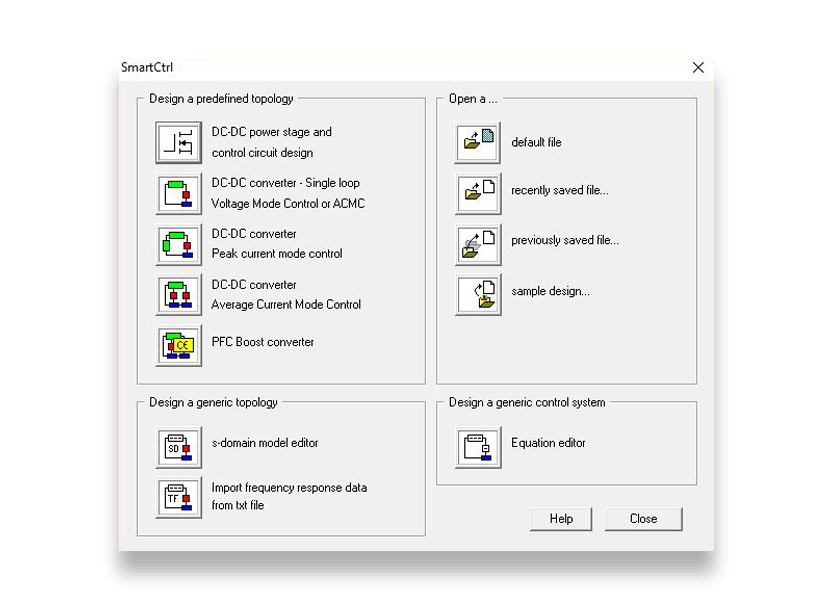

Topologies and control modes

![]()

In SmartCtrl you can design the control for a generic converter or use a predefined topology.

The predefined topologies are:

🔺 Forward converter

🔺 Flyback converter

🔺 Buck converter

🔺 Boost converter

🔺 Buck-boost converter

🔺 Phase Shifted Full Bridge converter with Voltage Mode Control and Resistive load

For each predefined topology or generic converter you can choose the following controls:

🔺 Voltage mode control

🔺 Average current mode control

🔺 Peak current-mode control

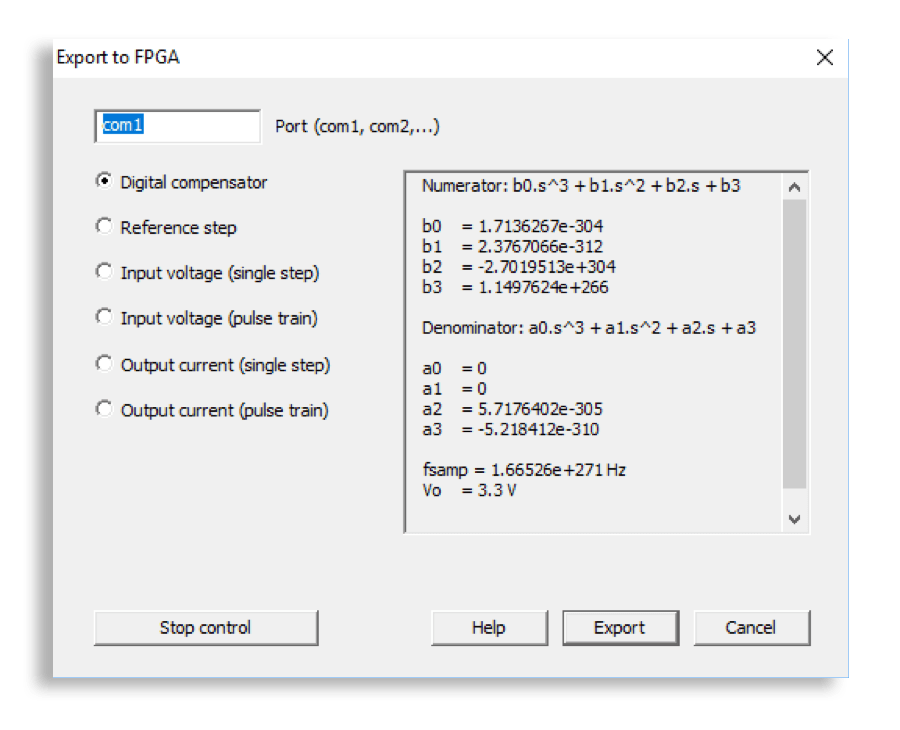

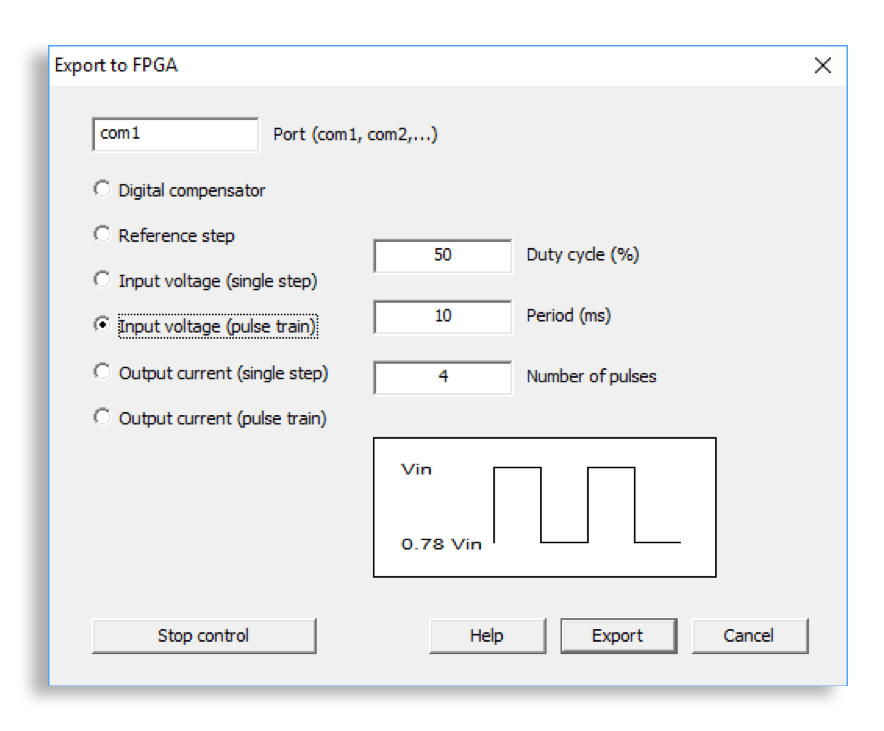

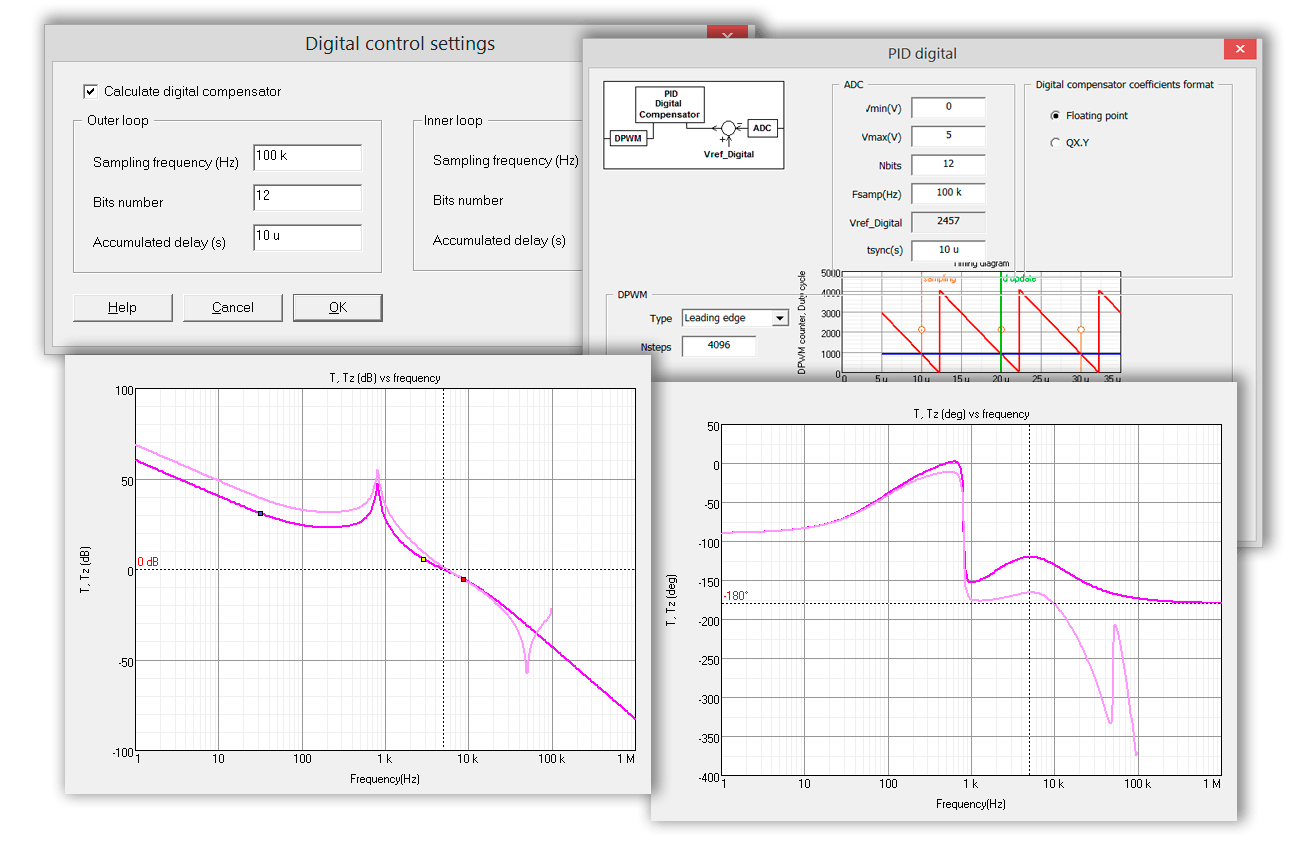

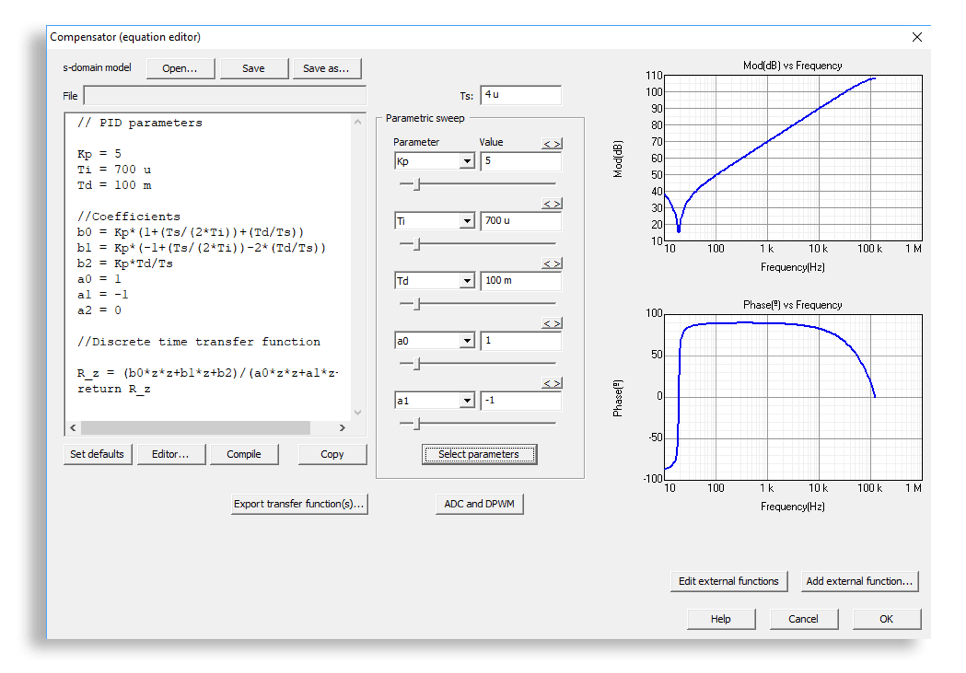

Get the Digital Control

![]()

Customers demand high-performance Power Electronics and Digital Control is the answer.

SmartCtrl Digital Control module Key features are the following:

🔺 Digital effects (DEFs) such as sampling frequency, DPWM delays, and rounding effects due to the limited bits number of compensator coefficients being considered.

🔺 New Bode plots considering DEFs are shown.

🔺 Sensitivity analysis of DEFs can be performed.

🔺 The designed digital compensator can be exported to PSIM in z-domain format.

In addition, in order to define a real DIGITAL control, SmartCtrl works directly in Z domain.

The power converter new modelling approach is based on multivariable z-domain models.

SmartCtrl allows the designer to work with discrete models to get the best performance and the highest bandwidths for the digital control loop.

Improve your design compared to S discretized models.

Plant, sensor and compensator can be defined in Z Domain (Z Z Z; Plant in Z domain, Sensor in Z domain and Compensator in Z domain)* or Multidomain Operation, mixing (S S Z, Plant in S domain, Sensor in S domain and Compensator in Z domain) * or any possible combination.

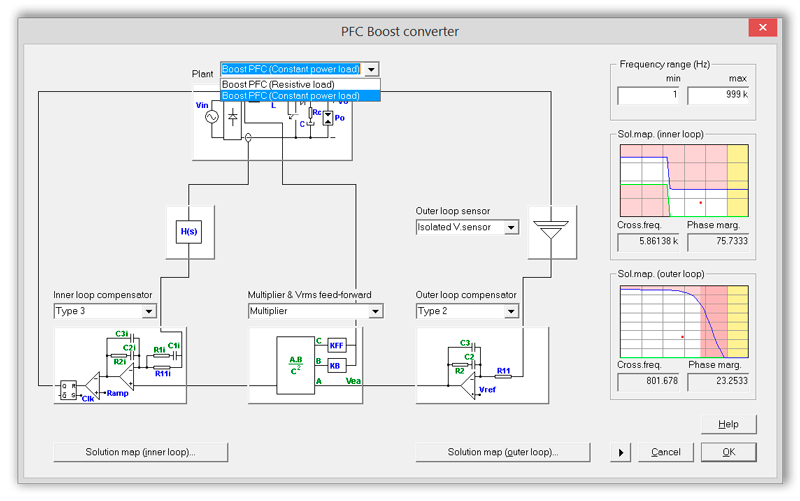

Power Factor Correction Tool

![]()

SmartCtrl has a PFC design tool (Power Factor Correction – Boost Converter). This tool incorporates a UC3854A controller as well as some other practical information, e.g. actual values of output voltage when a single-pole regulator is used as an outer loop compensator. The way to obtain a PFC design is as follows:

🔺 Firstly, select the type of multiplier and its parameter. Then, design the inner and outer loops using the provided solution maps. The results are depicted in several plots, including the expected waveforms at the output of the inner loop and the outer loop.

🔺 It is possible to export the PFC design to a PSIM schematic by simply clicking on the PSIM icon, including the power stage, the UC3854A controller, the components of the inner and outer compensators, the feedback loop and the oscillator.

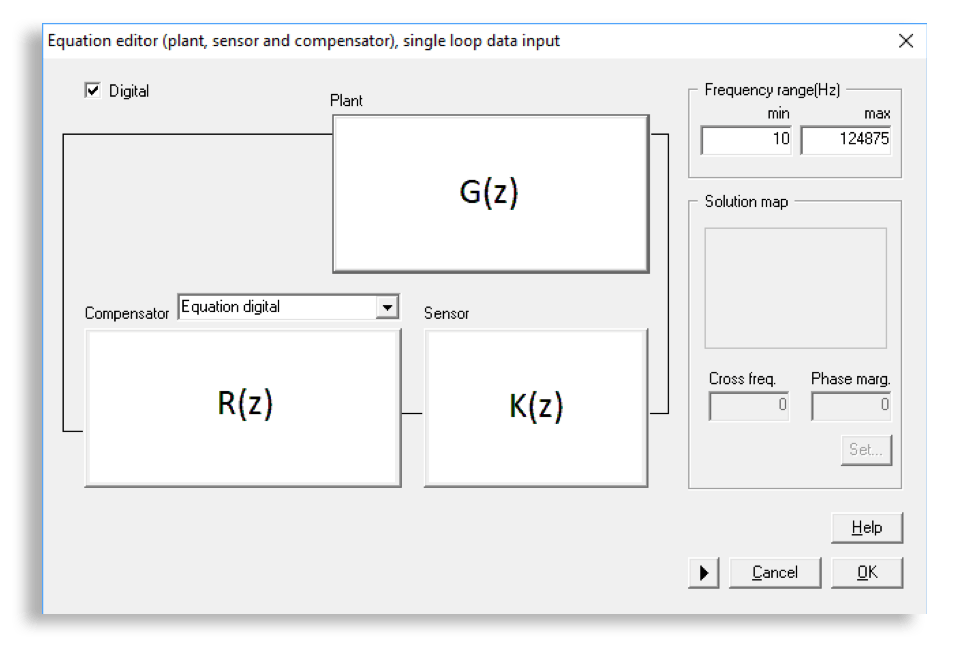

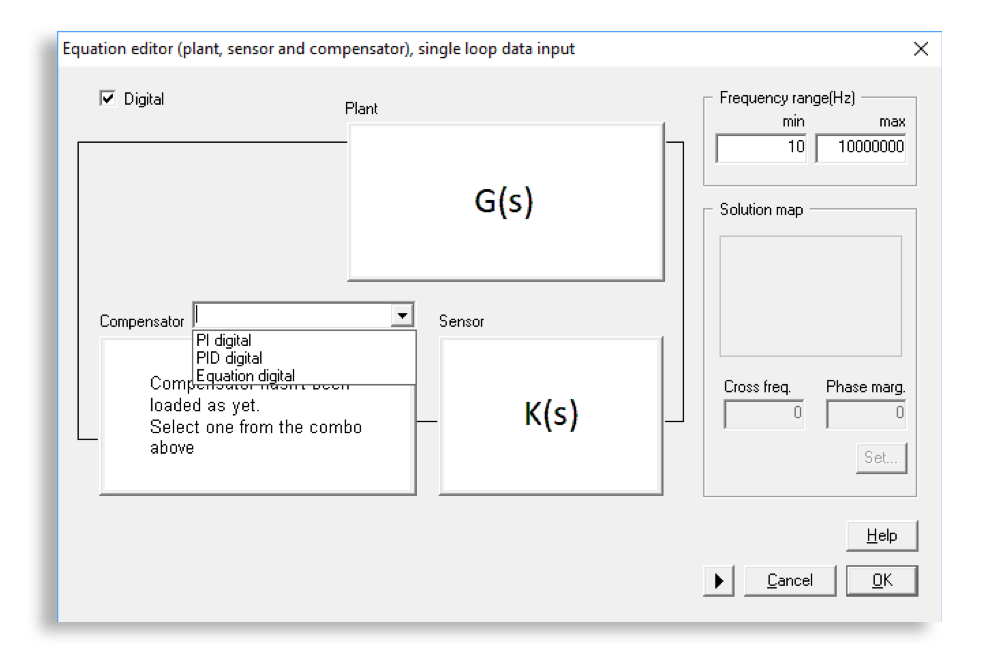

The equations editor

![]()

This built-in function supports the definition of customized plants, compensators and sensors transfer functions, through the “design a generic plant” and “design a generic control system” options.

It supports two different features:

🔺 Design a generic topology

In this case, the equations editor is used to define the plant transfer function of the converter, while the sensor is pre-defined. The compensator can always be selected among the pre-defined ones or user-defined with the equations editor.

🔺 Design a generic control system

In this other feature, the user is able to define the plant and the sensor transfer function using the equations editor, and for the compensator, the user can select among the pre-defined options (Analog or Digital) or define its own compensator.

🔺 Design a generic control system independently

Edit your plant model independently (out of the software flow) and generate dynamic models from its transfer function. Compare to other transfer functions.

Import

![]()

If you want to check your theoretical model or view the effects produced by modifying certain parameters of your converter or control, you can import transfer functions.

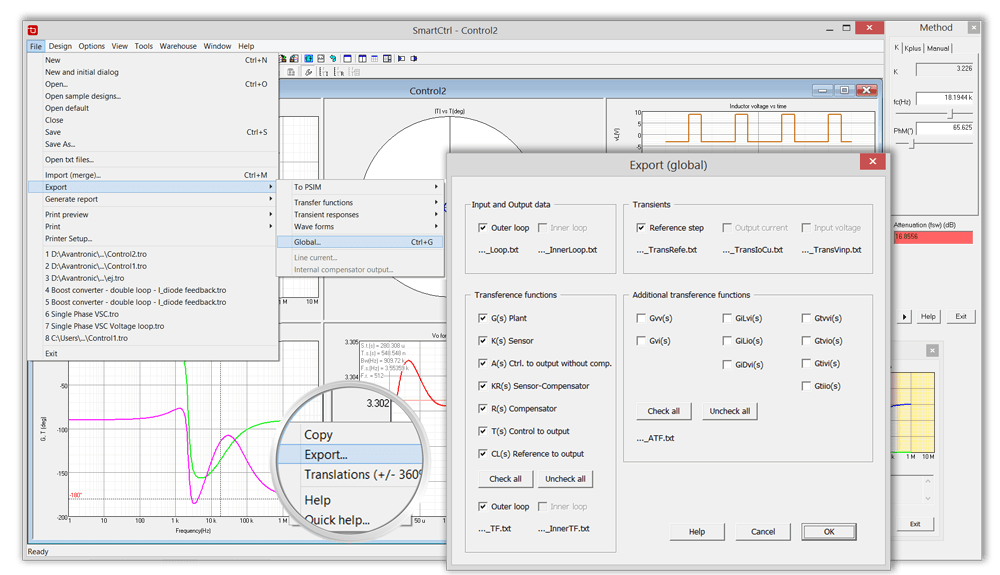

Export

![]()

By right-clicking on any of the sub-screens, you can export the information you need: transfer functions, waveforms and transient responses.

Furthermore, the export-global menu allows you to export entirely by selecting the desired options.

The numerical data of all transfer functions (plant, open-loop gain, closed-loop gain, etc.) and transient plots can be exported to PSIM, Mathcad, Matlab, Excel, etc. via a txt extension file.

Overall, there are several ways of exporting data in SmartCtrl:

🔺 Schematics to PSIM

🔺 Transfer functions (plant, compensator, open-loop, closed-loop, etc.)

🔺 Transient response

🔺 Input and output data

In addition, when designing a digital compensator, it is possible to export the design to a Zynq SoC device.